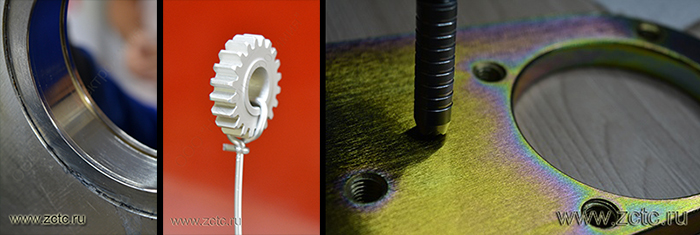

GALVANICS, ELECTROCHEMISTRY, METALWORKING

This section contains articles on electroplating and coatings. Questions of theoretical electrochemistry are considered. The properties of electroplated coatings are given. The mechanisms of deposition and corrosion are given in detail. The principles of choosing coatings for certain operating conditions are shown. The basics of chemical-galvanic processes in the production of printed circuit boards are given.

The section will be useful for electrochemical engineers, mechanical engineers, students, as well as amateurs and all those who are interested in electroplating both at work and at home.

Scientific Section Editor - Ph.D. Fazlutdinov K.K.

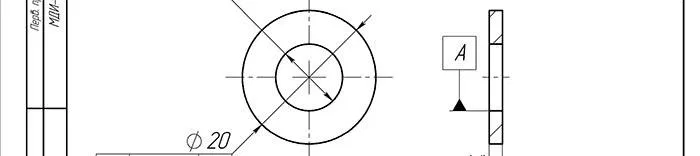

Designation of electroplated coatings on drawings

• Designation of coatings international according to DIN, ISO.

• The designation of coatings is Russian in accordance with GOST 9.306-85.

• Designation of coatings is special digital on fasteners in accordance with GOST 1759.4-87.

• Designation of coatings is special digital on cable lugs according to GOST 23981-80.

Theory of electrochemistry and galvanics

[General aspects]

• FAQ: Frequently asked questions about electroplating.

• Electroplating for beginners. In plain language.

• Double electric layer (DEL): concept and theory of structure.

• Life cycle of industrial water.

• Basic terms in electroplating.

• Polarization studies of the kinetics of galvanic processes.

• electrode potential. Polarization.

• The structure of the molecule and the structure of water in liquid, solid and gaseous form.

• The structure of aqueous solutions.

• Structuring of water under the action of external influences. Background and memory of water.

• Theoretical foundations of electroplating.

• Zero charge point.

• Physical and chemical properties of water. Facts about water and the anomalies of its behavior.

[Electrocrystallization]

• Effect of heat treatment on the structure of galvanized coatings.

• Defects in the crystalline structure of coatings.

• Dispersion of coatings (crystal size).

• Classification of crystalline structures of coatings.

• Features of electrocrystallization of alloys.

• Impurities in coatings.

• Reasons for the formation of internal stresses in electroplated coatings.

• The nature of the porosity of electroplated coatings.

• Hardness of electroplated coatings.

• Theoretical foundations of electrocrystallization of metals.

• Coating texture.

• Physical and chemical processes during heat treatment of coatings, part 1.

• Physical and chemical processes during heat treatment of coatings, part 2.

[Electroplating Design]

• Selection of power sources (rectifiers) for electroplating production.

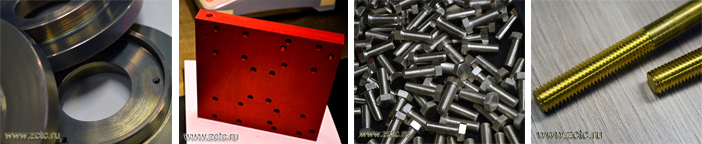

Applying technologies and coating properties. Deposition mechanisms. Coating structure

[Surface Preparation]

• Abrasive treatment of the metal surface, which improves the adhesion of coatings.

• Degreasing and etching of metal surfaces.

• Surface preparation of aluminum before applying metal coatings.

• Electrochemical polishing of stainless steel. Bath technology and compositions

• Electrochemical polishing of stainless steel. Mechanism and kinetics

• Chemical polishing of metals

[Oxide and Phosphate Coatings]

• Anodic oxidation of aluminum (anodizing).

• Anode oxidation of titanium (anodizing).

• Microarc oxidation of aluminum (MAO).

• Chemical oxidation of aluminum.

• Steel chemical oxidation (burnishing).

• Chemical phosphating of steel.

[Custom Metal Electroplating]

• Passivation of zinc coatings.

[Alloy Electroplating]

[Electroplated Precious Metals]

[Metal and Spav Chemical Coatings]

• Chemical nickel plating (nickel-phosphorus alloy).

• Chemical nickel plating (nickel-boron alloy)

• Chemical silvering.

[Processes involving dielectric metallization]

• Production of printed circuit boards.

[Other Coating Methods]

• Hot tinning.

• Thermal diffusion zinc plating.

• Thermal spraying of chromium coatings.

• Cold galvanizing (zinc coated paint coatings).

• Chrome plating. All methods (vacuum, diffusion, chemical, galvanic, thermal)

How to choose a cover?

• Choice of electroplated coatings by color.

• Heat resistance and heat resistance of various chrome coatings.

• Replacing the silver plating with a high tin copper-tin alloy (white bronze).

• Protective, protective and decorative, special coatings.

• Which chrome to choose: protective and decorative, hard, milky, matte, black?

• General principles for the selection and application of galvanic coatings.

• Determining the cost of electroplating.

• Advantages of hot phosphating over low-temperature (cold) phosphating.

• Comparison of zinc coatings (electroplating with pure zinc and its alloys versus other galvanizing methods).

What coatings are applied where?

• Electroplating in the automotive industry.

• Galvanic coatings in plumbing.

• Electroplating in the aerospace industry.

• Electroplating in the military industry.

• Electroplating in the railway industry.

• Electroplated coatings in the nuclear power industry.

• Electroplating in electrical engineering.

• Electroplating on tool (in development).

• Hot dip galvanizing in the production of steel reinforcement.

• Hot dip galvanizing in the production of roofing sheets.

• Sparking and spark proof tools

• Hard magnetic coatings for recording information on drives (nickel-cobalt)

• Nickel plating in a printing house: processing clichés and stereotypes.

• Tin-plating of stainless steel.

• Problems of electroplated copper plating in the production of printed circuit boards

• Applications of aluminum bipolar plates with chemical nickel coating for fuel cells

• Reflective electroplating coatings in the optical industry.

• Light-absorbing galvanic coatings in the optical industry

• Hard and milk chromium plating in the production of foundry and molds.

• Galvanizing of hardware on hangers instead of bulk galvanizing in a drum.

Coating features to consider when designing parts.

• FAQ: Frequently asked questions about electroplating.

• The influence of the method of manufacturing parts on the quality of electroplated coatings.

• Types of defects in electroplating

• Galvanic coating in bulk (bell, drum) and on hangers. Important points for the designer.

• What materials can be electroplated?

• General recommended requirements for parts supplied for electroplating

• Design features of aluminum products for galvanized coating.

• On hydrogenation of parts during galvanizing and cadmium plating and methods for its removal.

Corrosion of coatings and materials, protection against corrosion.

• Rejection signs of zinc coating

• Types of corrosion of metals and metal plating.

• Protective anticorrosive effect of galvanic coatings.

• Corrosion protection with paint coatings.

• Cathodic protection of underground pipelines.

• Corrosion of aluminum protected by chemical nickel or chrome plating.

• Durability evaluation of aluminum bipolar plates for fuel cells

• Protective protection against corrosion of metals using a magnesium sacrificial anode.

• Calculation of the corrosion behavior of contact pairs of metals.

• Chemical (corrosion) resistance of electroplated coatings in various environments.

About surface machining.

• The choice of steel grade for the manufacture of metal structures, depending on the required characteristics.

About chemical-thermal treatment of parts.

• Nitriding.

• Boriding.

• Hardening.

• Cementation.

About product molding.

• Production of copper busbars

Electroplating in motorcycle and auto tuning

Do you want to become our client?

Just leave your request by filling out the form on the right and we will contact you as soon as possible. Thank you!

By submitting an application, you agree to processing of your personal data. Your data is protected.