Designation: Z

Synonyms: White galvanized.

Price: from 10 rub. . per dm2

Close

Close

Please fill out the contact form so that we can process your request.

Close

Close

Your application has been successfully sent. We will contact you shortly. Please wait for the manager's call!

Continue workGalvanic coatings are an indispensable part of machine-building production. Galvanic coatings are divided into protective, protective-decorative and special. The purpose of protective coatings, such as galvanizing on hardware, shafts, housings, is to protect against corrosion. Protective and decorative coatings carry not only anti-corrosion properties, but also decorative. So, nickel-plating racks, brackets, handles and other products can not only protect them from corrosion, but also significantly improve their appearance. Special coatings, such as copper plating on tools or sleeves, are used to create special properties - spark protection, solderability, electrical conductivity, electrical insulation, etc. The division of coatings into protective, protective-decorative and special is conditional, because, for example, chrome coating combines corrosion protection, decorative properties (shine), wear resistance and heat resistance.

The choice of coating depends on the specific purposes and operating conditions of the entire product. Coatings that are resistant in some environments may be completely unsuitable for other environments. So, galvanized pipelines in cold fresh water are perfectly protected from corrosion, but they cannot be used in sea salt water or at high temperatures, because. Zinc ceases to protect the steel anodically. These conditions require the use of cadmium, special zinc alloys or phosphated zinc with oiling.

We offer a wide range of different galvanic and chemical coatings on steel, stainless steel, cast iron, aluminium, copper, zn-al-cu and other materials.

Designation: Z

Synonyms: White galvanized.

Price: from 10 rub. . per dm2

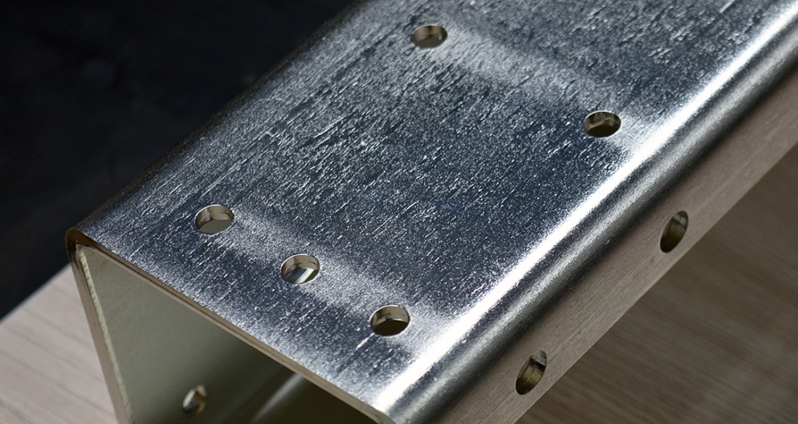

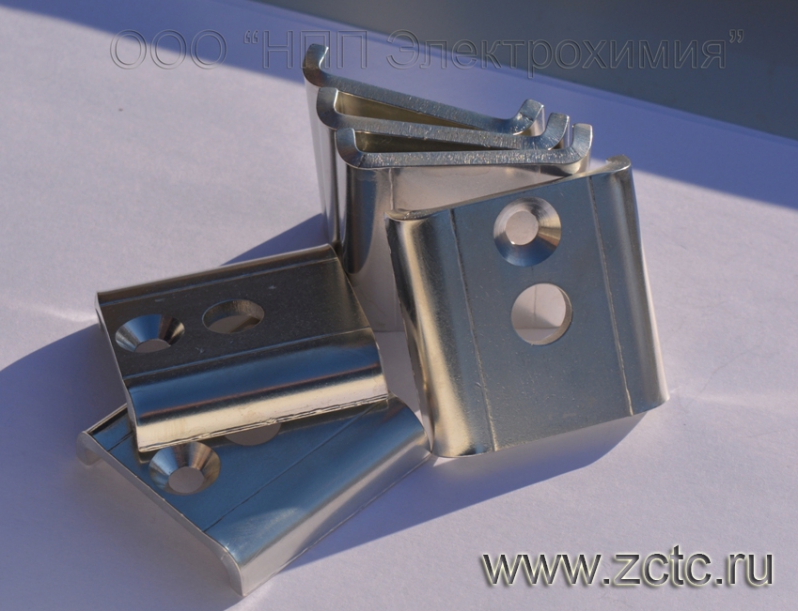

Designation: Z

Synonyms: White galvanized.

Price: from 10 rub. per dm2

Purpose: White galvanic zinc plating - one of the main anti-corrosion coatings on steel.

Designation: Z

Synonyms: Zinc yellow

Price: from 10 rub. per dm2

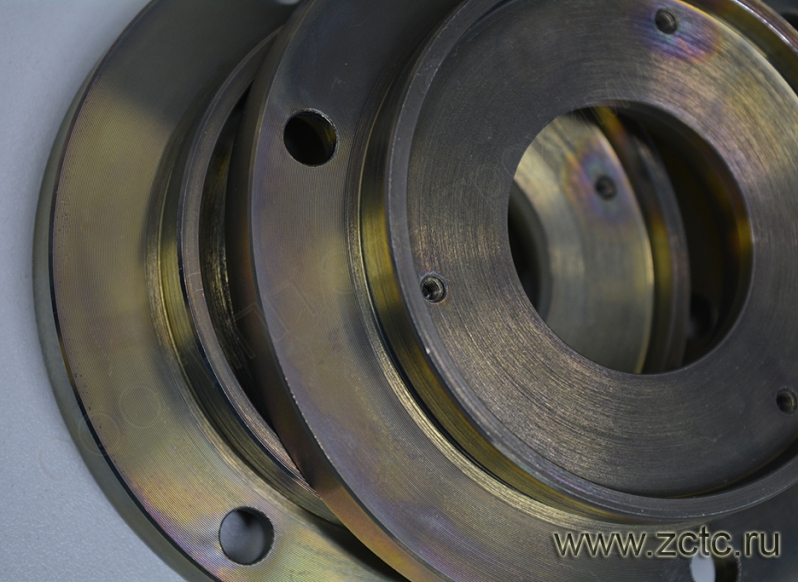

Designation: Zn

Synonyms: Yellow galvanized.

Price: from 10 rub. per dm2

Purpose: Rainbow galvanizing is the main anti-corrosion coating for steel springs. Yellow chromate plating significantly increases the protective properties of the coating, second only to khaki passivation in terms of corrosion resistance. Springs with a tensile strength above 1380 MPa are usually not galvanized without heat treatment.

Designation: Z.black

Synonyms: Black galvanized stainless steel.

Price: from 10 rub. per dm2

Purpose:Blackening (black galvanized) stainless steel is a decorative coating and, in combination with oiling in industrial oils, water emulsions or polymers, has good performance characteristics. Blackening of stainless steel is often used on hardware: bolts, nuts, washers, studs, etc. to create a decorative effect without greatly increasing the size of the thread.

Designation: Zn.t

Synonyms: White galvanized.

Price: from 10 rub. . per dm2

Purpose: White galvanizing with heat treatment - anti-corrosion coating for high-strength steels.

Designation: Zn.black

Synonyms: Black galvanized

Price: from 10 rub. per dm2

Designation: Zn.olive

Synonyms: Green galvanized, olive zinc.

Price: from 10 rub. per dm2

Purpose: Olive galvanizing - a powerful anti-corrosion coating for steel with the most durable chromate passivation "khaki". This type of chromating provides a significant increase in the protective properties of zinc due to the greatest thickness of the outer film compared to analogues. Olive galvanizing is most often used on military parts operating in harsh conditions.

Designation: Zn

Synonyms: Zinc with phosphate.

Price: from 10 rub. per dm2

Designation: Zn

Synonyms: Yellow galvanized.

Price: from 10 rub. per dm2

Purpose: Galvanic galvanizing of cast iron protects it from corrosion in atmospheric conditions and neutral, non-salty environments. The final rainbow chromatization increases the protective properties of the entire coating several times. Only olive chromate provides the best protection. Cast iron products are more difficult to process than steel products. This is due to the presence of a casting crust on them, the quality of which (density) can vary greatly. Cast irons with a porous casting skin are more difficult to coat. Also, on cast iron, the overvoltage of hydrogen evolution is lower, which facilitates this negative side reaction during alkaline galvanizing, unless special additives are used in the electrolyte.

Designation: Zn

Synonyms: White galvanized.

Price: from 10 rub. per dm2

Purpose: Colorless galvanizing of cast iron is used to protect parts from corrosion in dry, heated rooms (light operating conditions). In addition to this, chromium plating slightly increases the degree of gloss, which is important for cast iron parts, because they often have a high roughness after casting. The coating is free of toxic hexavalent chromium. Otherwise the coating is similar to rainbow zinc.

Designation: Zn-Ni

Synonyms: -

Price: from 10 rub. per dm2

Purpose: Zn-Ni - modified anti-corrosion coating for steel. Due to the 12-16% nickel content in the alloy, the coating becomes harder, more resistant to corrosion and high temperatures. The main application of the coating is in the automotive industry.

Designation: Zn

Synonyms: White galvanized.

Price: from 10 rub. per dm2

Purpose: Zn-Al-Cu coating is used primarily to improve the appearance of products. Corrosion protection also appears to some extent, although, in essence, Zn-Al-Cu itself already includes a large amount of zinc.

Designation: Sn-Bi

Synonyms: Tinning.

Price: from 10 rub. per dm2

Designation: Sn-Bi

Synonyms: Tinning.

Price:from 10 rub. per dm2

Purpose: Tin coating on copper busbars up to 3 meters is used to protect against corrosion, stabilize transient resistance, and prevent direct contact of the copper busbar with aluminum and galvanized steel (unwanted galvanic couple). Tin-bismuth improves solderability and creates easily break-in layers with movable electrical contacts. The coating improves the appearance of the products. Adding bismuth to the coating allows you to slow down the transition of the plastic white modification of tin to powder gray at temperatures below -30°C.

Designation: Sn-Bi

Synonyms: tin coating, tinning, tin plating

Price: from 10 rub. per dm2

Purpose: Tin coating is used to prevent direct contact of stainless steel with aluminum and copper (undesirable galvanic couple), to facilitate the running-in of parts, to seal threaded contacts and to ensure solderability. Adding bismuth to the coating allows you to maintain solderability for up to 1 year, slow down the transition of the plastic white modification of tin to powder gray, and eliminate needle formation during storage.

Designation: Sn-Bi

Synonyms: Tinning.

Price: from 10 rub. per dm2

Designation: Sn

Synonyms: Tinning.

Price: from 10 rub. per dm2

Purpose: Tin coating on steel is used for < undefined:p>improving solderability and electrical conductivity,

Designation: Sn

Synonyms: Tinning.

Price: from 10 rub. per dm2

Designation: Sn-Ni

Synonyms: Tinning.

Price: from 10 rub. per dm2

Purpose: Tin-nickel alloy containing tin 60% is characterized by high hardness, ductility and chemical resistance. To copper is the anode. The coating is more wear-resistant than nickel and much more uniform in thickness than chrome. The alloy is stable in concentrated nitric acid, dilute sulfuric and hydrochloric acids, saline environments, and 100% humid atmosphere. It has a high degree of gloss, is easily mechanically polished and retains solderability for a long time. Plastic.

Designation: Sn-Bi

Synonyms: Tinning.

Price: from 10 rub. per dm2

Purpose: Tin coating on aluminum is used to enhance corrosion resistance, improved solderability, elimination of contact of aluminum with copper conductors, creation of an easily break-in layer on rubbing surfaces. Without a technological copper or chemical-nickel sublayer, tin plating of aluminum is impossible. The thickness of the sublayers is usually minimal and such sublayers are not indicated on the drawing (unlike multilayer tinning).

Adding bismuth to the coating allows you to: maintain solderability for up to 1 year, slow down the transition of the plastic white modification of tin to powder gray, and level out needle formation.

Designation: Sn-Bi

Synonyms: Tinning.

Price: from 10 rub. . per dm2

Purpose: Multilayer tin coating on aluminum is used to ensure maximum corrosion resistance, improve solderability, protecting electrical contacts from oxidation and direct contact with copper, creating an easily break-in layer on rubbing surfaces.

Adding bismuth to the coating allows you to: maintain solderability for up to 1 year, increase frost resistance - slow down the transition of the plastic white modification of tin to gray powder at temperatures below -30°C, to prevent needle formation during storage.

Designation: Sn-Bi

Synonyms: Tinning.

Price: from 10 rub. per dm2

Purpose: Tin-lead coating on aluminum is used as a coating for soldering, as well as anti-friction and protective. In terms of corrosion resistance, it is inferior to the tin-bismuth alloy, but surpasses it in ductility. Tin-lead coating, like tin-bismuth, does not produce needles during storage and is stable at low temperatures, unlike pure tin. The appearance is gray, matte or semi-shiny. Can replace Horizontal POS coverage

Designation: Sn-Pb

Synonyms: Tinning.

Price: from 10 rub. per dm2

Designation: Sn-Bi

Synonyms: Tinning.

Price: from 10 rub. per dm2

Just leave your request by filling out the form on the right and we will contact you as soon as possible. Thank you!

By submitting an application, you agree to processing of your personal data. Your data is protected.