TIN-LEAD ON COPPER

Description

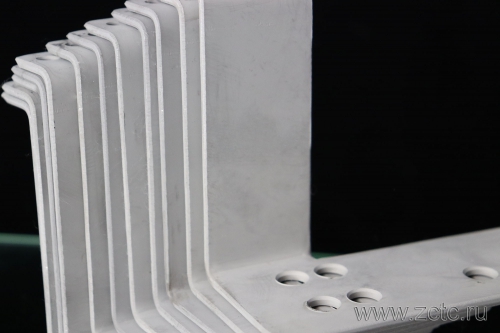

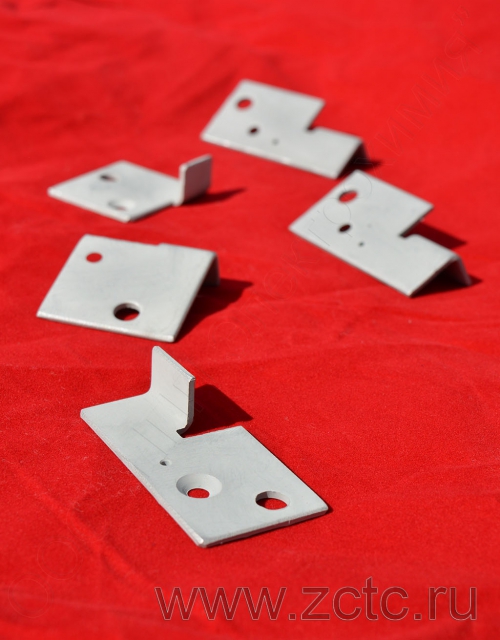

Tin-lead alloys have a light gray color, are easy to solder and retain the ability to solder for a long time (unlike pure tin), and provide good sintering of parts. Coatings with tin-lead alloys are used to protect products from corrosion, incl. in sea water, stabilizing transient electrical resistance, protecting copper from direct contact with aluminum, improving solderability, facilitating screwability while simultaneously sealing threaded connections. The alloy can be deposited in a very wide range of composition. The alloy containing 50% lead and tin each has the greatest chemical resistance. Tin-lead alloys with a tin content of 5 to 17% are used as anti-friction alloys, especially in combination with oils. Coatings of this composition also act as a lubricant when stamping parts from sheet steel. Typically, a tin-lead alloy composition of 60% Sn and 40% Pb by weight is used (analogous to hot tinning 60). The standard potentials of tin and lead are close (-0.136 and -0.126 V, respectively), so they are galvanically deposited from solutions of simple salts. Lead and tin do not form either solid solutions or chemical compounds. Can be easily brushed to improve appearance. You can order coating of copper and its alloys with tin-lead in accordance with GOST 9.305-84 by phone and email indicated in the section "CONTACTS".

Characteristics

|

Designation (examples) |

Sn-Pb |

|

Thickness |

9-100 microns (greater thickness is possible) |

|

Microhardness |

118-198 MPa |

|

Electrical resistivity at 18° C |

11.5⋅10-8 Ohm⋅m |

|

Permissible operating temperature |

200° C |

|

Lead content in Sn-Pb alloy |

30-50% |

Advantages of tin plating:

- The tin-lead alloy in atmospheric conditions is anodic in relation to copper and its alloys, therefore Sn-Pb protection can significantly increase the corrosion resistance of coated products, especially in the marine environment;

- Significantly increases the solderability of copper. Alloying the coating with lead allows you to maintain solderability for longer than one year;

- Resistant to sulfur-containing compounds and can be used on parts in contact with all types of plastics and rubbers;

- Exceptionally ductile, only pure lead is more elastic;

- Has some of the best anti-friction properties;

- Alloying with lead helps prevent “needle formation”, and also avoids destruction of the coating during operation below -30°C;

- Can replace the Hot-tinning coating in cases where it is necessary to obtain a thin layer, especially on threads and in the presence of holes.

Disadvantages of tin plating:

- Low wear resistance;

- The presence of lead does not allow the coating to be used for food purposes;

- The coating is unstable in an alkaline environment, primarily due to the etching of lead, which is not chemically combined with tin;

- Without brushing heterogeneous matte gray color and high roughness

Do you want to become our client?

Just leave your request by filling out the form on the right and we will contact you as soon as possible. Thank you!

By submitting an application, you agree to processing of your personal data. Your data is protected.