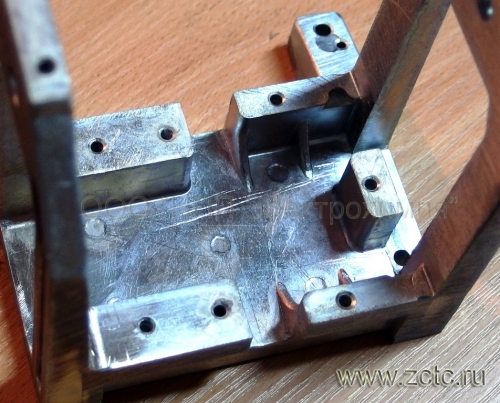

COLORLESS ZINCAMING Zn-AL-Cu

Description

White galvanizing is used for ZAM galvanizing most often to improve appearance and corrosion resistance. Shiny colorless zinc is similar in appearance to chromium or nickel, and this determines its scope of application as a conditionally decorative coating. However, you need to consider the possibility of zinc changing color and tarnishing over time, unlike chrome. In terms of protective ability, white galvanization is inferior to rainbow and olive. Depending on the required degree of protection of the metal surface (which is directly related to the class of environmental aggressiveness and the expected service life of the product), the thickness of zinc can range from 6 microns to 50 microns. The optimal coating thickness should be from 6 to 24 microns. The thickness of the white chromite film is no more than 0.025-0.08 microns; it does not contain hexavalent chromium. The durability of white zinc without additional treatment with polymer compounds in 5% salt spray is 20-80 hours. The use of a new solution for chromite plating allows increasing the resistance in the salt chamber to 240 hours. You can order TsAM galvanizing with colorless chromium plating in accordance with GOST 9.305-84 by phone and email indicated in the section "CONTACTS".

Characteristics

|

Designation (example) |

Zn |

|

Thickness |

6-50 microns (greater thickness is possible) |

|

Microhardness |

490-1180 MPa |

|

Electrical resistivity at 18° C |

5.75⋅10-8 Ohm⋅m |

|

Permissible operating temperature |

300° C |

Advantages of galvanizing:

- Zinc coating protects Zn-Al-Cu mechanically.

- It is not possible to directly chrome-plate ZN-AL-Cu, so chrome-plating of the coating is an excellent way to increase the corrosion resistance of the entire product.

- Zn-Al-Cu initially have an unattractive appearance. Galvanizing Zn-Al-Cu allows you to significantly improve the decorative characteristics of products made from Zn-Al-Cu. Chromium plating additionally creates a polishing effect.

- The coating ensures easy screwing of threaded parts.

- Chromite colorless films do not contain hexavalent chromium and meet the most stringent environmental requirements.

- The zinc coating can withstand bending and flaring.

Disadvantages of galvanizing:

- Chromite film on zinc is mechanically relatively fragile and loses its decorative appearance under the condition of periodic mechanical impact: touch of a tool, hands.

- The coating has increased brittleness at temperatures above 250°; C and below minus 70° C.

- The coating has low chemical resistance to the effects of products released during the aging of organic materials.

Read also articles

Galvanizing mechanism

Description of the galvanic galvanizing process. Electrolytes.

Hydrogenation and removal of hydrogenation of steel after galvanizing

The problem of hydrogenation during galvanizing. How to dehydrate?

Do you want to become our client?

Just leave your request by filling out the form on the right and we will contact you as soon as possible. Thank you!

By submitting an application, you agree to processing of your personal data. Your data is protected.