GALVANIZING STEEL WITH PHOSPHATING

Description

Galvanizing with phosphate passivation in appearance resembles amorphous phosphating of steel, performed in a cold way. It is gray, matte (sometimes semi-shiny), with rainbow stains and golden tints. The coating has increased corrosion resistance and, in combination with oiling, can be used instead of toxic cadmium coatings in harsh operating conditions (including in a saline environment, sea water, etc.). In an acidic environment, the corrosion resistance of phosphated zinc is several times higher than that of chromated zinc. Depending on the technical specifications, the thickness of the main zinc coating can vary from 6 to 50 microns. To replace cadmium, a minimum of 24 microns should be applied. The thickness and density of the outer phosphate film is usually not regulated. A distinctive feature of phosphated zinc is its exceptional adhesion to paint and varnish coatings. The corrosion rate of non-passivated zinc depends on pH:

You can order galvanizing of steel with phosphating in accordance with GOST 9.305-84 by phone and email indicated in the section "CONTACTS".

Characteristics

|

Designation (example) |

Zn.phos |

|

Thickness |

6-50 microns (greater thickness is possible) |

|

Microhardness |

490-1180 MPa |

|

Electrical resistivity at 18° C |

Dielectric |

|

Permissible operating temperature |

300° C |

Advantages of galvanizing:

- Phosphated zinc coating has excellent corrosion resistance. It is anodic in relation to steel and protects products from corrosion electrochemically and mechanically at temperatures up to 70°; C. Protection is evident even in a saline environment, provided that the products are oiled after coating. At temperatures higher than 70° At temperatures, protection becomes only mechanical. The anodic nature of the zinc coating’s protection allows it to protect steel products even in the presence of damage (scratches, pores, chips). In addition, according to GOST 9.305-84, zinc coating 24 microns with phosphating and oiling can be used instead of toxic cadmium coatings.

- Zinc coating with phosphating prevents contact corrosion of steel when mating with parts made of aluminum and its alloys.

- Galvanization with phosphating provides the best make-up of threaded parts, especially in combination with oiling, because The phosphate film itself is anti-friction (wear-resistant when working under friction).

- Zinc-based phosphate film has exceptional adhesion to paint and varnish coatings.

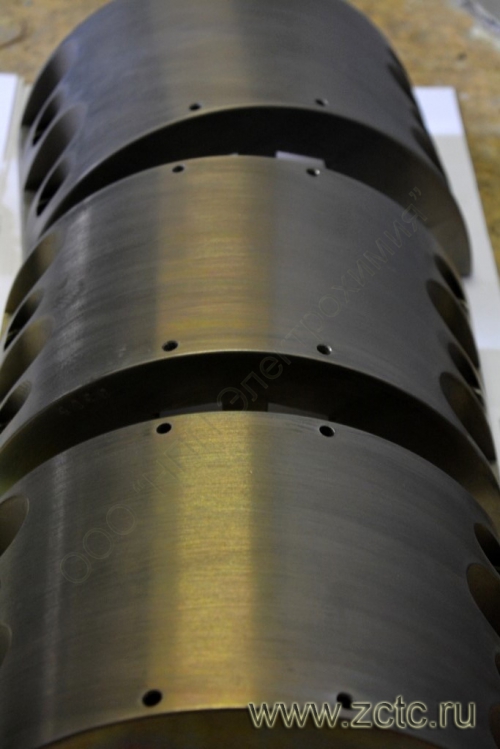

- Has a high thickness uniformity, which is confirmed by metallographic studies:

A microphotograph of a cross-section of the coating is shown below:

Disadvantages of galvanizing:

- The phosphate film on zinc is quite fragile.

- Electrochemical galvanizing with phosphating causes some loss of steel ductility due to hydrogenation. Steels with a tensile strength higher than 1380 MPa are not subject to galvanizing.

- Zinc has increased brittleness at temperatures above 250°; C and below minus 70° S.

Read also articles

Galvanizing mechanism

Description of the galvanic galvanizing process. Electrolytes.

Hydrogenation and removal of hydrogenation of steel after galvanizing

The problem of hydrogenation during galvanizing. How to dehydrate?

Do you want to become our client?

Just leave your request by filling out the form on the right and we will contact you as soon as possible. Thank you!

By submitting an application, you agree to processing of your personal data. Your data is protected.