TIN-Bismuth ON STEEL. BRILLIANT

Description

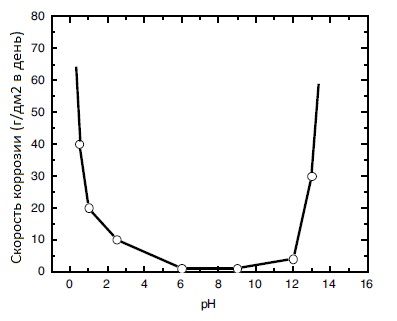

Tin is a corrosion-resistant metal and, in the absence of pores and damage, perfectly protects steel from corrosion in various environments, including. in organic acids. Tinning is widely used in electrical engineering and instrument making for coating steel contacts, current-carrying busbars and grounding busbars. The resistivity of tin is 8.5 times less than that of steel, and the transient resistance is stable over time. Tin-bismuth solders perfectly. Often, tin coating is used as a separating layer between steel and copper/aluminum contacts to prevent contact corrosion. Tin coating has proven itself well when covering elements of water heaters, incl. heating elements. The introduction of bismuth into the alloy makes it possible to operate coated parts at temperatures below -30°C, when pure tin undergoes the transformation of a compact white modification (β-Sn) into powdery gray (α-Sn). Bismuth also retains the ability of the coating to be soldered for a year after application. The corrosion rate of pure tin depending on the pH of the medium is shown in the figure:

Can be either shiny (mirror) or semi-shiny/matte.

You can order shiny tinning of steel with tin-bismuth alloy in accordance with GOST 9.305-84 by phone and email indicated in the section "CONTACTS".

Characteristics

|

Designation |

Sn-Bi |

|

Thickness |

6-100 microns (greater thickness is possible) |

|

Microhardness |

118-198 MPa |

|

Electrical resistivity at 18° C |

11.5⋅10-8 Ohm⋅m |

|

Permissible operating temperature |

200° C |

|

Bismuth content in Sn-Bi alloy |

0.2-2% |

Advantages of tin plating:

- The tin coating in atmospheric conditions is cathodic in relation to steel and, in the absence of pores and damage, perfectly protects it from corrosion. In many organic environments, tin becomes an anode to steel and begins to protect it from corrosion not only mechanically, but also electrochemically. Tin coating is resistant to sulfur-containing compounds and is recommended for parts in contact with all types of plastics and rubbers.

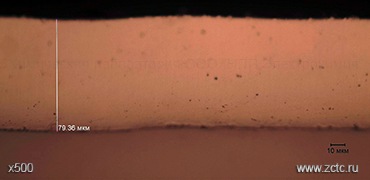

- Brilliant tin coating low porosity with a layer thickness of over 5 microns, while matte tin coating is characterized by significant porosity. Because of this, a high-gloss tin coating provides better corrosion protection. The porosity of coatings of small thickness (up to 5 microns) can be reduced by melting the coating.

- Tin coating improves steel solderability. A shiny coating retains solderability for a longer time than a matte coating. Alloying the coating with bismuth allows it to maintain solderability for longer than a year.

- Tin-bismuth improves the electrical conductivity of the steel surface and stabilizes the contact resistance.

- The coating has good adhesion to the base metal, a low coefficient of friction (facilitates sliding and screwing), elasticity, and can withstand bending, drawing, flaring, stamping, and press fit within certain limits. The shiny coating has excellent thickness uniformity, which is confirmed by metallographic studies:

- Alloying with bismuth (0.5-2%) allows you to avoid destruction of the coating during operation below minus 30°; C;

- After coating, the steel acquires a beautiful silver-white shiny color. Due to less porosity, the shiny surface is not “grabbed” by the fingers, as in the case of a matte finish.

Disadvantages of tin plating:

- Low wear resistance;

- Low corrosion resistance with a thickness of up to 5 microns, as well as in recesses, in welded and soldered seams;

- Insufficient ductility and lower anti-friction properties compared to tin-lead and lead;

- The presence of bismuth in the composition does not allow the coating to be used for food purposes;

- The coating is moderately resistant to alkalis, but still corrodes slowly, especially when heated;

Do you want to become our client?

Just leave your request by filling out the form on the right and we will contact you as soon as possible. Thank you!

By submitting an application, you agree to processing of your personal data. Your data is protected.