TIN-BISMUTH ON TITANIUM

Description

Tinning of titanium is based on two aspects.

First, tin has 36.5 times lower electrical resistance than titanium. This is not the best indicator - the resistance of copper is 250 times lower than that of titanium. However, its contact resistance is unstable due to oxidation in air. In addition to oxides, the surface film of copper may contain hydroxides and sulfides. The oxidation process is ongoing and the surface of the copper coating conducts current less and less each time. Unlike copper, tin coating quickly passivates and its contact resistance becomes relatively constant. To combine the positive properties of copper and tin, a multilayer coating is used, for example, 24 microns of copper and 6 microns of tin-bismuth, which simultaneously provides excellent electrical conductivity and stable contact resistance.

The second point is that in addition to good electrical conductivity, shiny tin plating gives titanium parts the ability to be soldered, makes them easier to slide and significantly improves their appearance.

Doping the coating with bismuth prevents the transition of the white modification of tin (β-Sn) to the gray modification (α-Sn) at temperatures below -30° C, which is accompanied by the transformation of the coating into powder ("tin plague").

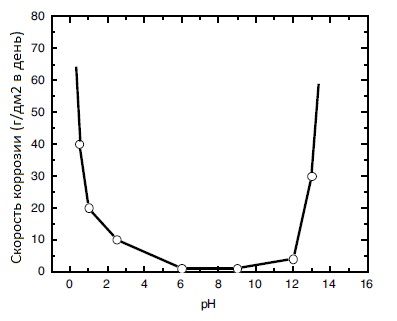

When using coated parts, the difference in corrosion resistance between titanium and tin should be taken into account. The corrosion rate of pure tin depending on the pH of the medium is shown in the figure:

You can order shiny tinning of titanium with a tin-bismuth alloy in accordance with GOST 9.305-84 by phone and email indicated in the section "CONTACTS".

Characteristics

|

Notation example |

Sn-Bi |

|

Optimal range of thicknesses |

6-100 microns (greater thickness is possible) |

|

Microhardness |

118-198 MPa |

|

Electrical resistivity at 18° C |

11.5⋅10-8 Ohm⋅m |

|

Permissible operating temperature |

200° C |

|

Bismuth content in Sn-Bi alloy |

0.2-2% |

Advantages of tin plating:

- High electrical conductivity and stable contact resistance.

- Tin-bismuth facilitates the soldering of titanium parts and retains solderability for more than a year.

- Brilliant tin plating improves the aesthetic properties of titanium.

- Has anti-friction properties, facilitates sliding and screwing.

- Tin-bismuth alloy resists alkalis at room temperature longer than titanium.

- Alloying with 0.5-2% bismuth avoids destruction of the coating during operation below -30°C.

Disadvantages of tin plating:

- The coating is not resistant to some environments in which titanium itself does not corrode, such as nitric acid and concentrated chromic anhydride.

- Insufficient ductility and higher coefficient of friction compared to tin-lead and lead.

- Not suitable for food environments due to bismuth.

Do you want to become our client?

Just leave your request by filling out the form on the right and we will contact you as soon as possible. Thank you!

By submitting an application, you agree to processing of your personal data. Your data is protected.