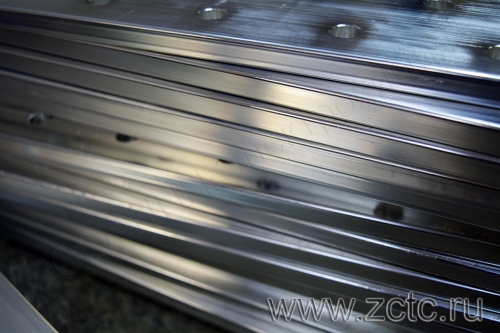

TIN plating of long-length copper bars up to 3m. BRILLIANT

Description

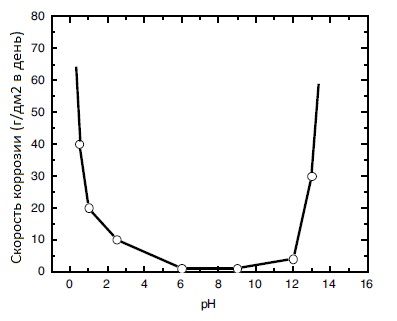

An important requirement for large-sized current-carrying copper busbars is the constancy of electrical resistance at the point where the contacts are connected. The process of oxidation (corrosion) of copper leads to the formation of thick oxide films with increased resistance, which can lead to failure of finished products or severe heating inside the equipment. To protect copper from oxidation, tinning is used with a tin-bismuth alloy. In addition, tinning eliminates the formation of an undesirable and dangerous galvanic couple between copper and electrical contacts made of aluminum or steel. It also improves the appearance of the tires, giving them a silver, shiny appearance. Thus, tinning is the main coating in electrical products. The corrosion rate of pure tin depending on the pH of the medium is shown in the figure:

A feature of tinning long copper busbars is the need to equalize the current along the entire length of the product. If there is too much current in the area, the coating will form “burnt”, and if there is little current, it will be dull, rough and of insufficient thickness.

Selective (partial) tinning of individual tire surfaces is possible.

You can order shiny tinning of long copper busbars with tin-bismuth alloy in accordance with GOST 9.305-84 by phone and email indicated in the section "CONTACTS".

Characteristics

|

Designation (example) |

Sn-Bi |

|

Thickness |

6-100 microns (optimal, greater thickness is possible) |

|

Microhardness |

118-198 MPa |

|

Electrical resistivity at 18° C |

11.5⋅10-8 Ohm⋅m |

|

Permissible operating temperature |

200° C |

|

Bismuth content in O-Vi alloy |

0.2-2% |

Advantages of tin plating:

- Tin stabilizes the transient electrical resistance of a long copper bus due to the anodic nature of protection against oxidation. Tin itself is easily passivated and its resistance does not change over time. The protective properties of a shiny coating are superior to those of a matte finish.

- Gloss up to mirror-like, in contrast to the traditional matte gray tinning. Doesn't get caught by hands and doesn't get scratched.

- Improves the solderability of copper busbars, which is often required for permanent contacts.

- Does not react with sulfur-containing substances that may be present, for example, in industrial atmospheres, unlike copper and silver, therefore, in such an environment, tin is not coated with a film of sulfides, which increases the contact resistance.

- The tin-coated copper bar can be bent due to the high ductility of the coating.

- Bismuth-doped tin easily withstands low temperatures (below -30°C), and the coating does not crumble due to the transition of the plastic modification of tin to a powder form.

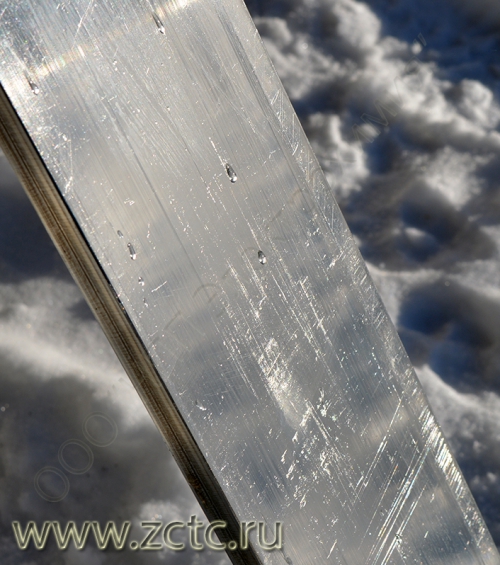

- High uniformity in thickness, even on complex-profile tires, which is confirmed by metallographic studies:

Disadvantages of tin plating:

- Low wear resistance.

- Inferior to lead and POS in ductility and anti-friction properties.

- Subject to corrosion in an alkaline environment when exposed for long periods of time, especially at elevated temperatures.

Read also articles

Galvanizing mechanism

Description of the galvanic galvanizing process. Electrolytes.

Hydrogenation and removal of hydrogenation of steel after galvanizing

The problem of hydrogenation during galvanizing. How to dehydrate?

Do you want to become our client?

Just leave your request by filling out the form on the right and we will contact you as soon as possible. Thank you!

By submitting an application, you agree to processing of your personal data. Your data is protected.