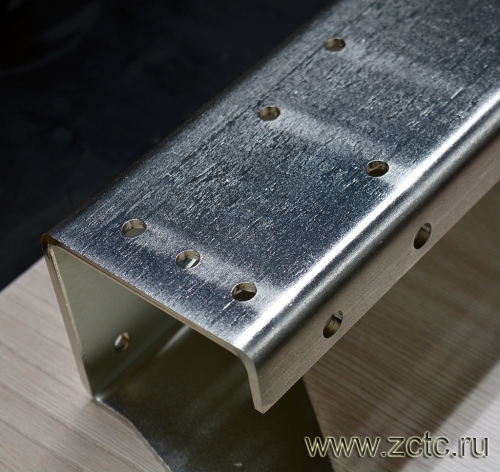

ZINC-PLATING STEEL COLORLESS

Description

White galvanic galvanization is most often used to protect steel parts from corrosion in light conditions operation, for example, in dry heated rooms. Colorless shiny zinc is somewhat similar in appearance to chrome or nickel, and this determines the scope of its application as a conditionally decorative coating. But you need to take into account the possibility of color change and tarnishing of the coating over time, unlike, for example, chrome. In terms of protective ability, white galvanization is inferior to rainbow and olive. Depending on the required degree of protection, the thickness of zinc can range from 6 to 50 microns. The optimal coating thickness should be 9 microns and above. The thickness of the chromite film is no more than 0.025-0.08 microns; it does not contain hexavalent chromium. The durability of white zinc without additional treatment with polymer compounds in 5% salt spray is 20-80 hours, sometimes more. The use of modern solutions for chromite plating allows you to increase it to 240 hours. The corrosion rate of non-passivated zinc depends on pH:

Shiny coatings are harder and less ductile than semi-shiny ones. The type of passivation has virtually no effect on microhardness. The electrical resistivity is greater than that of metallurgical due to the inclusion of carbon (up to 1%) and sulfur from the electrolyte in the coating composition. The transition resistance varies depending on the passivation method. Colorless film will have the lowest resistance.

You can order white galvanizing of steel according to GOST 9.305-84 by phone and email specified in the section "CONTACTS".

Characteristics

|

Designation (example) |

Z |

|

Thickness |

6-50 microns (greater thickness is possible) |

|

Microhardness |

490-1180 MPa |

|

Electrical resistivity at 18oC |

5.75×10-8 Ohm⋅m |

|

Permissible operating temperature |

300o C |

Advantages of colorless galvanizing:

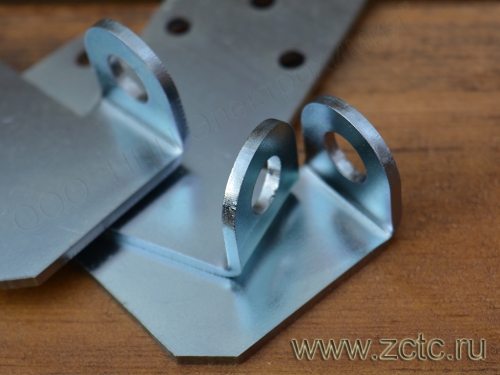

- White zinc coating is anodic to steel and protects it from corrosion up to 70°; C. At higher temperatures the coating is cathodic. The anodic nature allows the coating to protect steel products even in the presence of damage: scratches, pores, chips.

- Chromium plating, along with increasing corrosion resistance, also improves the appearance of galvanized products due to the effect of chemical polishing.

- Chromite colorless films do not contain toxic hexavalent chromium and comply with European environmental requirements.

- Like other types of zinc, white zinc prevents contact corrosion of steel when combined with parts made of aluminum and its alloys.

- Ensures easy screwing of threaded parts.

- Can be used for crimping plastics at temperatures above 100°; S.

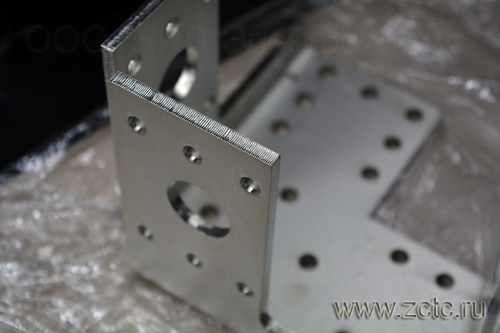

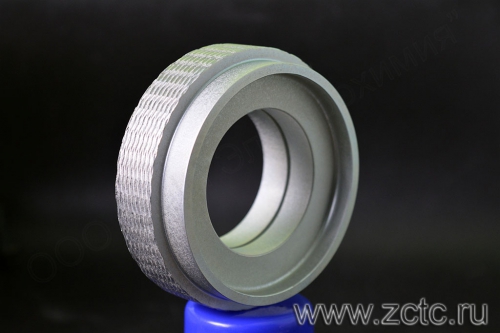

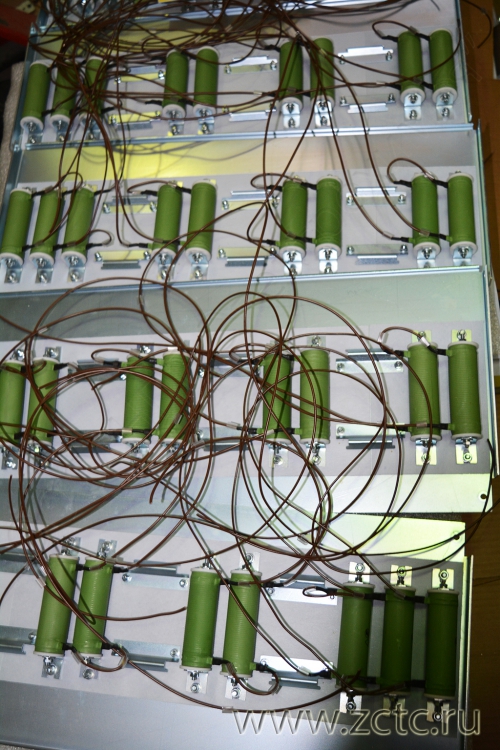

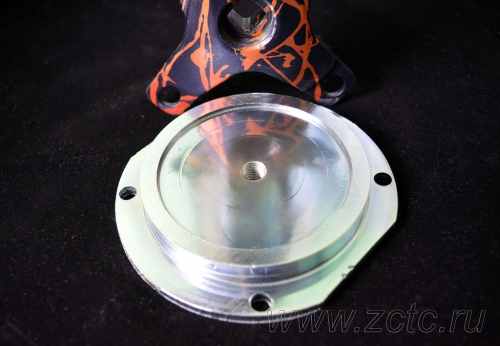

- The white zinc coating produced at our enterprise is ductile, withstands bending and flaring, thanks to the use of unique shine-forming additives in the electrolyte. It also has a high uniformity in thickness, which is confirmed by metallographic studies:

A microphotograph of a cross-section of the coating is shown below:

Disadvantages of colorless galvanizing:

- Chromite film on zinc is very thin and mechanically relatively weak. It loses its decorative appearance under constant mechanical influence.

- Electrochemical galvanizing causes some loss of steel ductility due to hydrogenation. Steels with a tensile strength higher than 1380 MPa are not subject to galvanizing.

- Zinc has increased brittleness at temperatures above 250°C and below minus 70°C.

- White zinc coating is poorly resistant to the effects of products released during aging of organic materials.

- Colorless chromite film does not have the property of “self-healing”. It is not able to restore its properties in case of minor mechanical damage, such as scratches, unlike chromate films.

Read also articles

Galvanizing mechanism

Description of the galvanic galvanizing process. Electrolytes.

Hydrogenation and removal of hydrogenation of steel after galvanizing

The problem of hydrogenation during galvanizing. How to dehydrate?

Do you want to become our client?

Just leave your request by filling out the form on the right and we will contact you as soon as possible. Thank you!

By submitting an application, you agree to processing of your personal data. Your data is protected.