Fazlutdinov K.K.

Fazlutdinov K.K.

03.03.2018 (updated 11.05.2021)

03.03.2018 (updated 11.05.2021)

12368 views

12368 views

The mechanism of chemical oxidation of aluminum. Structure and properties of the oxide obtained by the currentless method.

Symbol: Chem.ox, Chem.ox.e

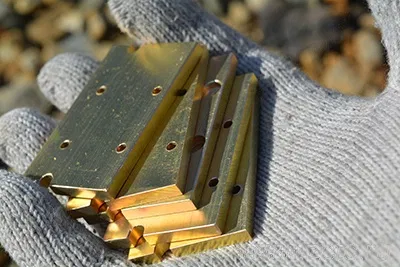

To increase corrosion resistance, products made of aluminum and its alloys are subjected to chemical, electrochemical and microarc oxidation (MAO). Oxidizing aluminum not only improves its corrosion resistance, but also increases hardness and wear resistance, heat resistance, heat resistance, modifies various electrical properties (electrical insulating or electrically conductive), and also improves appearance.

The oxide layer on oxidized aluminum has a microporous structure and therefore has a high adsorption capacity, which increases the adhesion of paint coatings to the surface of parts.

The thickness of the chemically produced oxide film on aluminum is typically 0.5-4µm. Films obtained by chemical oxidation of aluminum are inferior in terms of performance to anodic and MAO films, however, they have technological and economic advantages when coating complex and large-sized products, the internal surfaces of long and thin-walled pipes, large welded structures, and also in cases where electrical conductivity is required on surface of oxidized aluminum.

Chemical oxidation of aluminum and its alloys is carried out in alkali-chromate, phosphate-chromate and chromate-fluoride solutions.

Alkaline chromate oxide films are less than 2 µm thick and have poor mechanical properties, and are mainly used as a primer.

Phosphate-chromate solutions form oxide films on aluminum of greater thickness - 3-4 microns with higher protective and physical and mechanical properties. These oxide films are used for corrosion protection and as a primer for painting.

Oxide films on aluminum from chromate-fluoride solutions are thin, but dense, and have low electrical resistance. They are used to obtain a conductive oxide coating.

Do you want to become our client?

Just leave your request by filling out the form on the right and we will contact you as soon as possible. Thank you!

By submitting an application, you agree to processing of your personal data. Your data is protected.